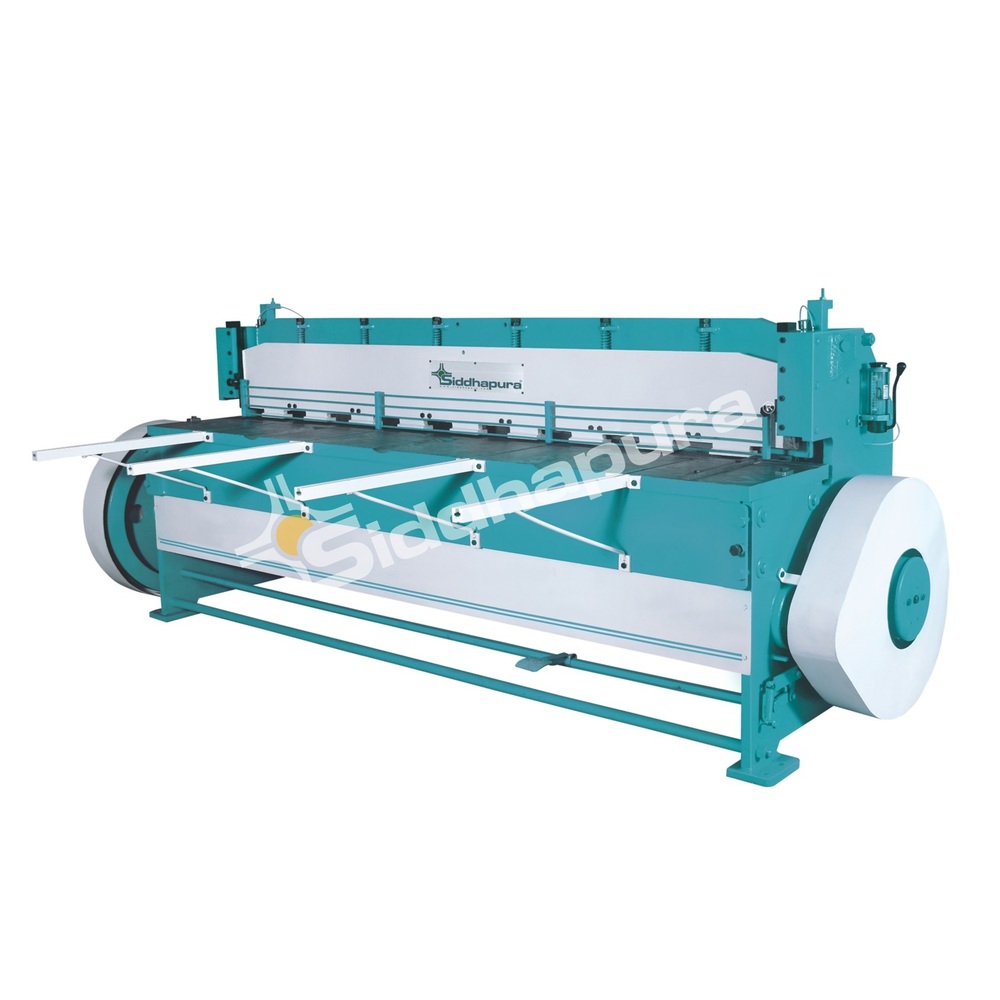

HYDRAULIC SHEARING MACHINE

1500000 INR/Unit

Product Details:

- Type Hydraulic Shearing Machine

- Material Metal

- Computerized Yes

- Automatic Grade Automatic

- Control System PLC Control

- Voltage 220-440 Volt (v)

- Warranty 1 Year

- Click to View more

X

HYDRAULIC SHEARING MACHINE Price And Quantity

- 1500000 INR/Unit

- 1 Unit

HYDRAULIC SHEARING MACHINE Product Specifications

- Automatic

- Yes

- Hydraulic Shearing Machine

- 1 Year

- Metal

- 220-440 Volt (v)

- PLC Control

HYDRAULIC SHEARING MACHINE Trade Information

- 25 Unit Per Month

- 1-4 Week

- All India

Product Description

Hydraulic Shearing Machine Conventional DRO

In order to serve our clients in a satisfying manner we are relentlessly engaged in manufacturing and exporting Hydraulic Shearing Machine Conventional DRO These machines are manufactured using grade material acquired by some reliable vendors of the industry which enables us to produce supreme quality products meeting industrial parameters Offered by us these machines are available in various models and specifications as per the clients requirements Known for its robust build and excellent characteristics Hydraulic Shearing Machine Conventional DRO is hugely demanded in international markets

Features

Adjustable for different jobs and materials

Efficient cutting

Robust structure

Simple functioning

Other Details

Specifications

Model

Shearing

Length mm

Shear Thic

Rake Angle

MinMax

Rake Angle

Rake Angle Range

StrokesMinute

at Min Max

Rake Angle

Hold

downs

Holding Force Kgs

Power HP

Over all Diamensions in mm

L x W x H

Approx Weight Kgs

MS

SS

LHVR325

2500

3154

23

1o15

052o

2813

13

2500

5

3150 x 2000 x 2400

3800

LHVR330

3000

3154

23

1o15

052o

249

16

2500

5

3500 x 2000 x 2400

4400

LHVR412

1250

46

34

1o37

053o

3317

5

4000

5

2000 x 2000 x 2400

2700

LHVR415

1500

46

34

1o37

053o

3015

8

4500

5

2250 x 2000 x 2400

3200

LHVR420

2000

46

34

1o37

053o

2813

11

6200

75

2750 x 2000 x 2400

3500

LHVR425

2500

46

34

1o37

053o

268

13

8000

75

3400 x 2350 x 2450

5200

LHVR430

3000

46

34

1o37

053o

246

16

10000

10

4000 x 2350 x 2450

6000

LHVR440

4000

46

34

1o45

053o

226

20

12000

10

4500 x 2350 x 2450

8500

LHVR615

1500

68

46

1o45

053o

248

9

6600

10

2250 x 2350 x 2500

4000

LHVR620

2000

68

46

1o45

053o

227

11

6500

10

2750 x 2350 x 2500

4300

LHVR625

2500

68

46

1o45

053o

288

14

8500

15

3400 x 2350 x 2500

6200

LHVR630

3000

68

46

1o45

053o

246

16

10800

15

4000 x 2350 x 2500

7000

LHVR640

4000

68

46

2o

053o

246

20

13600

20

5100 x 2700 x 2800

8400

LHVR815

1500

810

68

2o

053o

2210

9

10500

15

2250 x 2600 x 2650

5000

LHVR820

2000

810

68

2o

053o

188

11

12500

15

2750 x 2600 x 2650

5500

LHVR825

2500

810

68

2o

053o

248

14

16300

20

3500 x 2600 x 2650

6800

LHVR830

3000

810

68

2o

053o

206

16

18500

20

4200 x 2600 x 2650

7700

LHVR840

4000

810

68

2o

053o

208

20

23000

25

5200 x 2900 x 2800

13500

LHVR1015

1500

1013

810

2o

053o

2010

9

10500

15

2250 x 2650 x 2700

5500

LHVR1020

2000

1013

810

2o

053o

188

11

12600

15

2750 x 2650 x 2700

6000

LHVR1025

2500

1013

810

2o

053o

248

14

17500

20

3600 x 2650 x 2700

8000

LHVR1030

3000

1013

810

2o

053o

206

16

20000

20

4200 x 2650 x 2700

10500

LHVR1040

4000

1013

810

2o

053o

186

20

25000

30

5200 x 2900 x 2900

15200

LHVR1320

2000

1316

1013

2o

13o

135

11

16500

20

2750 x 2650 x 2950

7000

LHVR1325

2500

1316

1013

2o

13o

1510

13

32000

25

3600 x 2650 x 2950

9600

LHVR1330

3000

1316

1013

2o

13o

126

16

37000

25

4200 x 2650 x 2950

11800

LHVR1340

4000

1316

1013

2o

13o

104

20

22000

30

5200 x 3000 x 3050

17800

LHVR1620

2000

1620

1316

2o

13o

137

11

20000

25

2750 x 2950 x 3150

12000

LHVR1625

2500

1620

1316

2o

13o

158

13

40000

30

3600 x 2950 x 3150

12000

LHVR1630

3000

1620

1316

2o

13o

126

16

43500

30

4250 x 2950 x 3150

15300

LHVR1640

4000

1620

1316

2o

13o

104

20

30000

30

5200 x 3050 x 3500

21500

LHVR2020

2000

2025

1620

2o

13o

168

11

32000

40

2900 x 2950 x 3150

17000

LHVR2025

2500

2025

1620

2o

13o

158

13

48000

40

3600 x 2950 x 3150

18000

LHVR2030

3000

2025

1620

2o

13o

126

16

52000

40

4250 x 2950 x 3150

20000

LHVR2040

4000

2025

1620

2o

13o

104

20

30000

50

5200 x 3050 x 3500

24000

Capacities rated for MS of UTS 45kgmm2 Yield 28 kgmm2 SS of UTS 72 kgmm2 Yield 45 kgmm2 Machine will not cut any thickness variation beyond rated capacity for any length Right to change specification features accessories without notice reversed Compliance with safety requirements as per local regulations is responsibility of the user All Diamensions are in mm

Standard Feature

Moving beam synchronized by differential cylinders

Hardened rollers guide beam for constant blade gap

Rake angle adjustable to suit thickness and material

Blade gap adjusted with levers for clean cuts

Automatic control shearing

Sheets clamped hydraulically before cut starts

Shearingclamping forces adjustable to suit job

Both blades premium HCHCr four usable edges

Cutting length and position adjustable for shorter jobs

Beam returns on releasing foot switch for smaller cuts

Cutting area illuminated for clear view of blades

First two holddowns spaced closer at both ends

Squaring arm 1000mm at left with hardened lines

Squaring arm 600mm at right Helps distribute wear

Front gauging with stops scale on squaring arm

Hardened rods recessed table for easy sheet feeding

Sheet supports 1000mm long help support long plates

Ramp on rear slides out cut sheets outside shear area

Back gauge moves away trapping of cut sheets

Foot switch movable for operation from safe position

Finger safety guard with clear view of lighted cutting area

Dependable global of hydraulics electricals

Efficient compact power pack with minimal piping

Electricals neatly wiredlabelled for trouble shooting

Optional Accessories

Sheet front feeding system

NC backgauge with ball screw

Hydraulic rear sheet support

Automatic control shearing

Sheet rear stacking system

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Shearing Machine ' category

Back to top